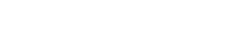

VERICOR POWER SYSTEMS announced today a new version of the TF Series gas turbine specifically developed for hydraulic fracturing applications. Rated at 5,000 hp, the TF50F combines features and benefits from Vericor’s proven marine and industrial engine product lines for oil field pump drive and electric power generation applications.

With twenty years of demanding service in the US Navy Landing Craft Air Cushion or LCAC, the TF series engine has earned a reputation for toughness and reliability – a requirement of oil field service.

The compact size of the TF engine, which traces its roots to helicopter propulsion, reduces the footprint and increases mobility for generation and hydraulic fracturing equipment.

The TF50F can operate on both gaseous and liquid fuel, make the changeover under power and operate 100% on well head gas while meeting all Tier 4 emission requirements.

“This is really a game changer ”says Richard Clinton, Vericor President and CEO, “The TF50F will offer producers and well service operators cost savings of over 80% vs. larger and heavier diesel engines”.

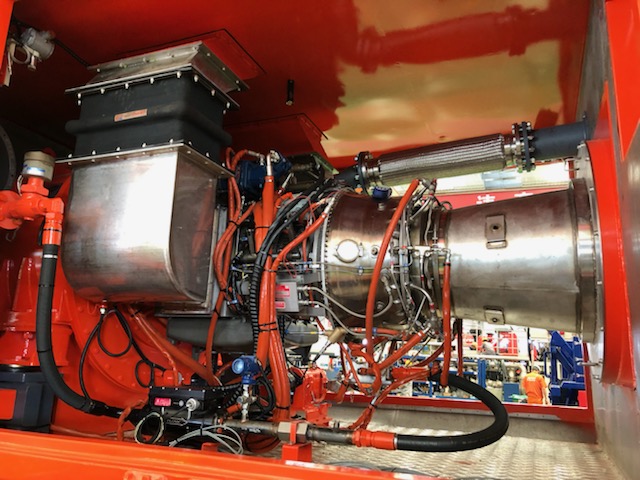

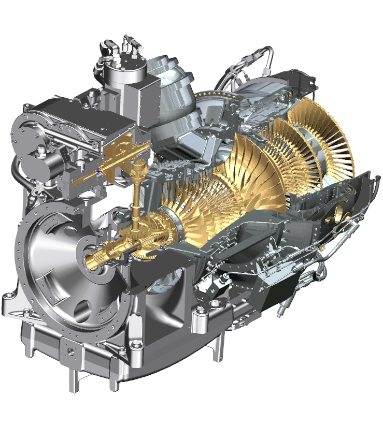

As with all Vericor gas turbines, the TF50F is a two shaft, free turbine engine and is designed to accept a high torque application such as hydraulic fracturing pump drives. The free turbine design means that only a speed reduction gearbox is required, eliminating the need for a transmission which is often a reliability issue in most operations. Extensive testing verified that the power section will deliver the required pumping torque and operational flexibility for not only current 2500 hp pumps, but also for the next generation of larger pumps.

“We envision that an oil field operator can significantly reduce the amount of equipment at a single spread by using gas turbine engines in place of diesels” Clinton said. “In fact, we see a single TF engine replacing two diesel driven pumps, reducing the amount of machinery in a frac spread and giving oil service operators a whole new game plan”.