Success StoryCogeneration plant: Gas turbine enables continuous power and steam for beverage manufacturer

Natural gas is converted to useful energy at a fraction compared to grid powerMore About Vericor's ASE50B

The Challenge

Provide a reliable and cost effective power and steam solution for beverage processing facility, 24 hour, 7 day per week of 3.2 MW of power

Vericor's Solution

Install a Vericor ASE50 Gas Turbine in cogeneration with a fired heat recovery steam generator

The Result

Cogen plant with Vericor gas turbine has logged about 77,000 hours with an equivalent energy cost that is a fraction compared to grid power and conventional boilers.

Overview

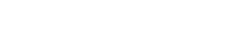

One of Japan’s major beverage manufacturers has successfully employed gas turbine cogeneration to provide plant electrical power and baseload steam production for various heating applications throughout the process.

Installed on the exterior of the main processing facility is a state-of-the-art cogeneration system that supplies reliable and high quality electrical power 3.2 MW and 20,000 kg/hr of 13.7 bar(g) saturated steam.

Vericor’s packager in Japan installed one of their own natural gas fired ASE50 Gas Turbine Generator Sets to offset grid power and to produce steam in lieu of conventional boilers. The exhaust heat is captured and combined with a supplemental duct burner to satisfy the high steam demand of the beverage manufacturing process.

The ASE50 engine is capable of starting from stop to full load in less than a few minutes, giving remarkable flexibility to the operators to mitigate unknown power and fuel outages in this critical application.

Installed on the exterior of the main processing facility is a state-of-the-art cogeneration system that supplies reliable and high quality electrical power 3.2 MW and 20,000 kg/hr of 13.7 bar(g) saturated steam.

Vericor’s packager in Japan installed one of their own natural gas fired ASE50 Gas Turbine Generator Sets to offset grid power and to produce steam in lieu of conventional boilers. The exhaust heat is captured and combined with a supplemental duct burner to satisfy the high steam demand of the beverage manufacturing process.

The ASE50 engine is capable of starting from stop to full load in less than a few minutes, giving remarkable flexibility to the operators to mitigate unknown power and fuel outages in this critical application.

Product Spotlight

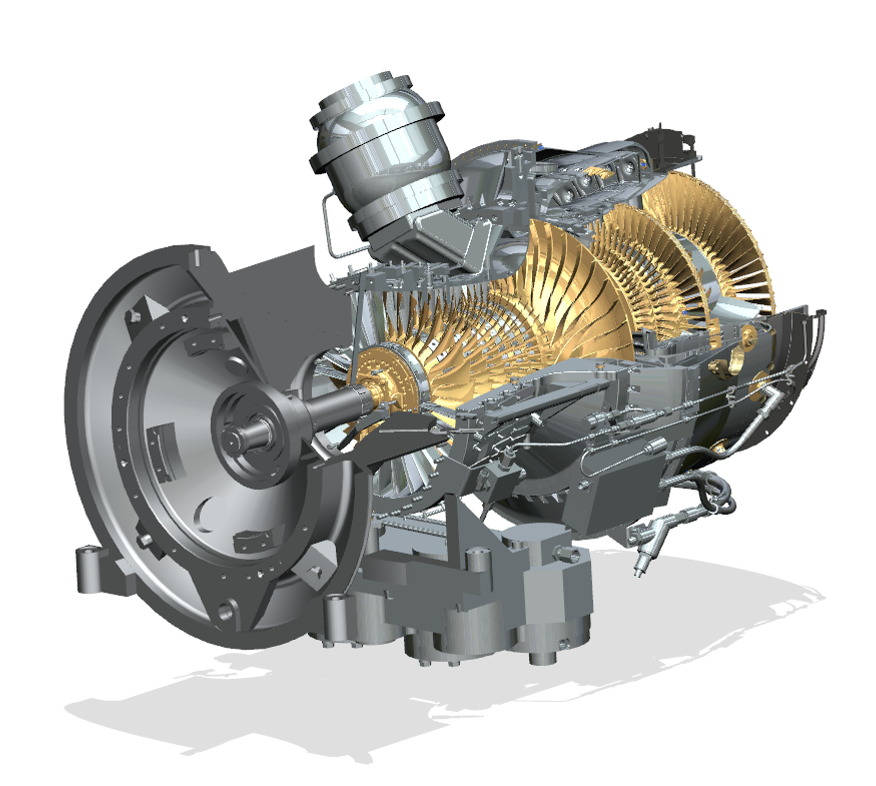

ASE50B

Industrial Gas Turbine

The Vericor ASE50B aero-derivative industrial gas turbine is used for power generation and mechanical drive applications across a range of industries such as oil & gas, industrial, commercial and institutional.